Connect with one of the oldest and premier Electrical and Turnkey Project contractors in Bangalore

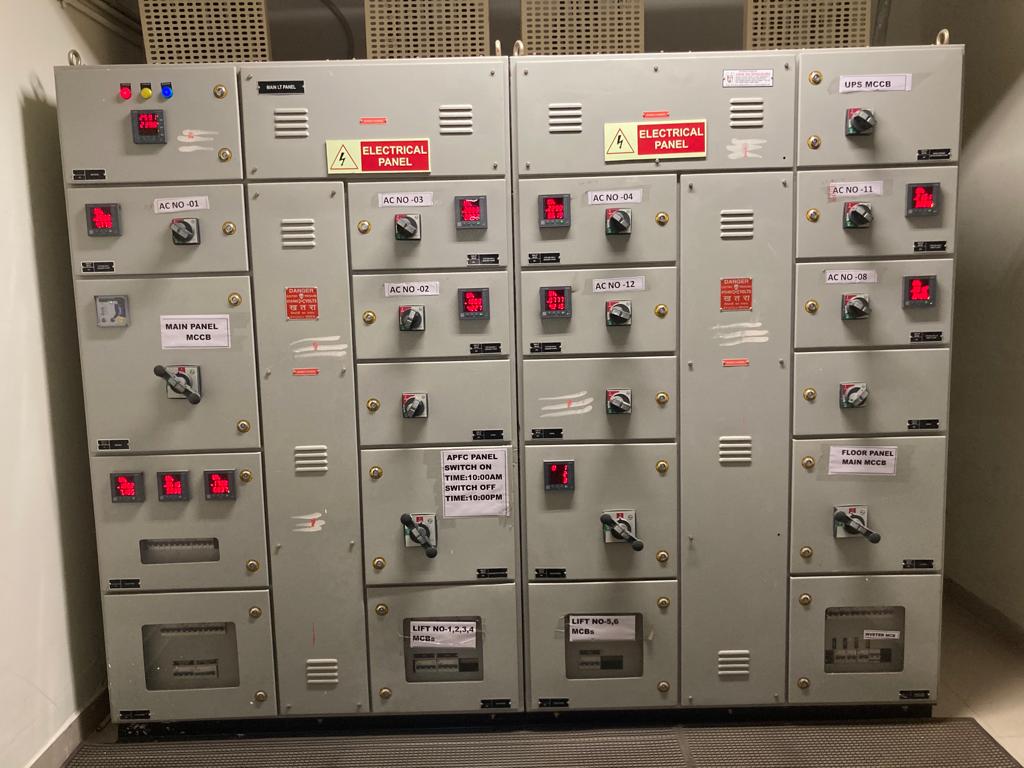

SA Electricals is a Bangalore based Electrical HT/LT and Trunkey Projects contracting company powered by passion and dedication. We believe in quality Installing of electrical infrastructure and focus on timely completion of your projects. You can name anything under the roof of electricals and its applications, and we are here to give you jaw dropping designs and concepts. Understanding our client needs, adding value to the requirements, and converting dream into reality is where SA Electricals is defined by our brand.

Residential Projects and Commercial Projects Timely completion of projects Customized and designed as per client requirements Complete turnkey projects planning | Concept >Idea> Designing > Execution levaraging modern technology & Installation procedures.